We investigated whether Adventurer3 could use free slicer software other than FlashPrint.

In the beginning

At first glance, it seems that there is Slic3r and cura for free slicer software soft of famous place. cura is from Ultimaker, and slic3r is open source.

cura just touched a little the other day, but I was interrupted once I could understand it.

I decided to download and use slic3r once before purchasing Simplify3D, but as it is not usable in the Adventurer 3 as it is, and since it was the beginning of the 3D printer challenge, I can not understand the right or left, settings etc. I gave up not to understand.

Since slic3r is open source, I can trace the contents from the source code, so I decided that I could investigate it.

About parameters

slic3r uses setting values classified into 3 at the time of G code output.

- Printer setting

- Filament setting

- Print configuration

These classified setting values are combined at the time of actual printing and output as a G code file.

Device settings

Basically, it is stored in the printer settings.

At the time of output to G code, adjustment of actual output data is performed by the setting of Firmware in this setting.

The following Firmware settings are available in 1.3.0.

- RepRap (Marlin/Sprinter)

- Repetier

- Teacup

- MakerWare (MakerBot)

- Sailfish (MakerBot)

- Mach3/LinuxCNC

- Machinekit

- Smoothieware

In Simplify3D, although I could fine-tune in the firmware setting, Slic3r can use only the above, and I can not fine-tune the setting contents.

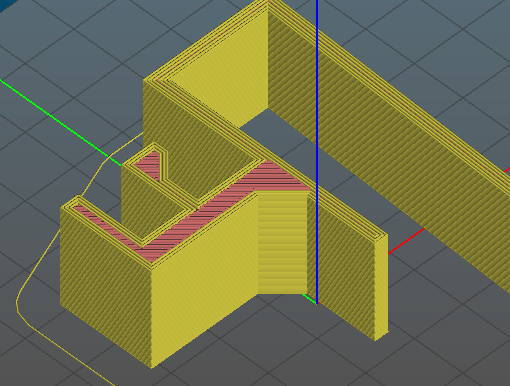

What is the setting for Adventurer3?

Set the bedshape to 150×150, the origin to 75×75, and set the number of extruders for capabilities to 1, and turn on the heat bed.

I wish I could present the correct firmware, but there was no match. The closest is RepRap.

The following settings are entered in Start G-code of Custom G-code.

G90

M82

M107

M140 S[first_layer_bed_temperature] T0

M104 S[first_layer_temperature] T0

M104 S0 T1

M108 T0Output location likely to be a problem

The following points are likely to be a problem with G code files that output firmware as RepRap.

Temperature setting code

M104 S215 ; set temperature

M140 S55 ; set bed temperatureIn FlashPrint, the bed temperature is M140 and the end is T0.

The code in the header part got along with the setting of the custom code in the printer setting, but there is no way to fix the temperature change part in the middle layer.

Z axis movement speed

There seems to be no way to set parameters individually.

At first, I saw the code, but it used the same movement speed as XY travel. Isn’t it really?

I’m scared to try this G code, but I’m afraid I can move the Z axis at the same speed as the XY travel speed.

Output method of XY movement speed at injection

G1 F1800

G1 X-23.186 Y25.871 E5.29730

G1 X-25.946 Y25.871 E5.36015In this way, the movement speed and the actual movement instruction are separated.

Although there seems to be no problem as the format specification of the G code, as far as the output of other slicer software is seen, there is nothing that separates the speed and the movement, so it becomes an uneasy material.

Even though XY travel and retract etc. are specified with G1 command, why is this so separated?

Imagine that the implementation may have been cumbersome.

Retract operation output

The same as Simplify 3D, but it hasn’t fired yet, there was an initial retract action.

Can be used in

It is scary to use the output data as it is even if you change the settings. Especially the movement speed of Z axis.

You need to modify the output.

However, the only place to add is the code output of Z-axis movement speed and temperature setting, so it may not be a lot of trouble.

コメント